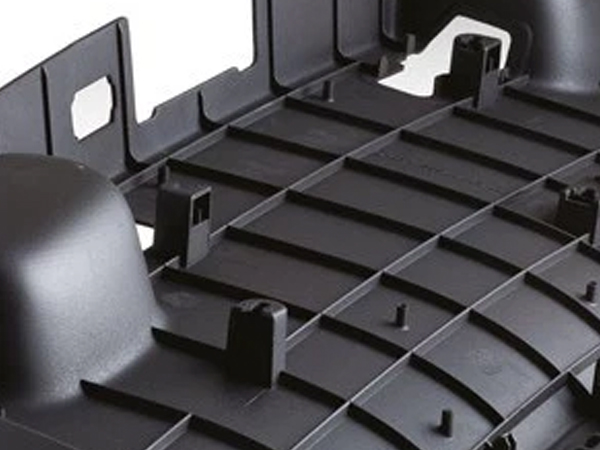

Polyurethane parts

Polyurethane capabilities at WCM use various tooling methods to suit a variety of production requirements including Vacuum Casting and RIM

If you’re looking for a low cost tooling option and rapid production time then the Polyurethane option may be the most suited route to meet your project needs. WCM offer 4 routes to create Polyurethane parts:

Polyurethane Processes

- Vacuum Casting

- RIM

- Super RIM

- Reinforced RIM

Each Polyurethane method offers specific features to meet your part requirements across size, accuracy, surface finish and quantity. The Prototyping team supports customers through the selection process to determine which method best suits their needs.

Polyurethane Examples

Vacuum Casting

- High accuracy

- Quality surface finish

- Suited to lower volume needs

RIM

- Low cost tooling option

- Greater accuracy of parts over Vacuum Casting

- Strong and high impact resistant materials

Super RIM

- Ideal for larger automotive parts

- Yields higher quantities with silicon tooling

- Lower investment than traditional methods

Reinforced RIM

- Fast production for automotive applications

- Large parts up to 7KG weight and 2.2m diameter

- RRIM press machinery to produce parts

WCM supports many leading automotive OEM brands through the Prototyping division in delivering high quality Polyurethane parts across all four routes