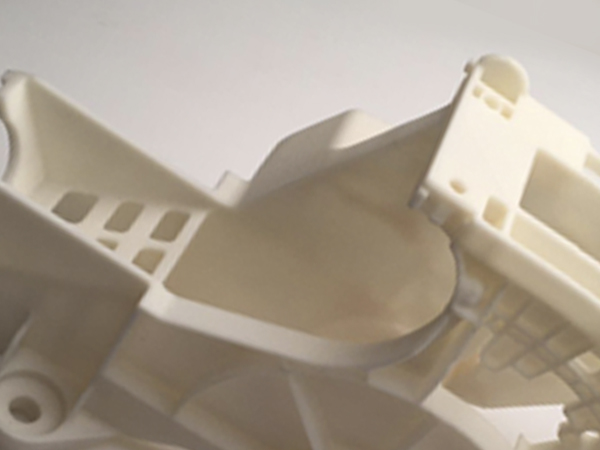

SLA & SLS PARTS

Operations across the UK deliver rapid 3D printed parts, offering a range of material resins and finishing services to meet your needs

Stereolithography (SLA)

The SLA process at WCM provides project teams with one off verification models, multiple engineering and marketing samples, to first off production intent parts in production materials. A number of SLA materials are used for parts, allowing specific characteristics such as water resistance, durability and high impact strength to be incorporated into the part.

Selective Laser Sintering (SLS)

The SLS process produces highly accurate parts that are ideal for testing functionality before progressing to tooling/series manufacture. WCM works with Nylon to deliver robust parts that provide rapid feedback to designers and engineers upon their latest CAD data.

By having the opportunity to analyse key engineering factors early on in the design process, improvements can be made before committing to further design/engineering investment, reducing the likelihood of changes when entering production.

Experts in Prototyping processes and techniques support customers through the selection process, making sure your parts are made using the appropriate process and materials