casting

WCM has developed two radical processes know as TMC (Tool-Less Metal Castings) for producing castings quicker than ever before, without the need for traditional tooling

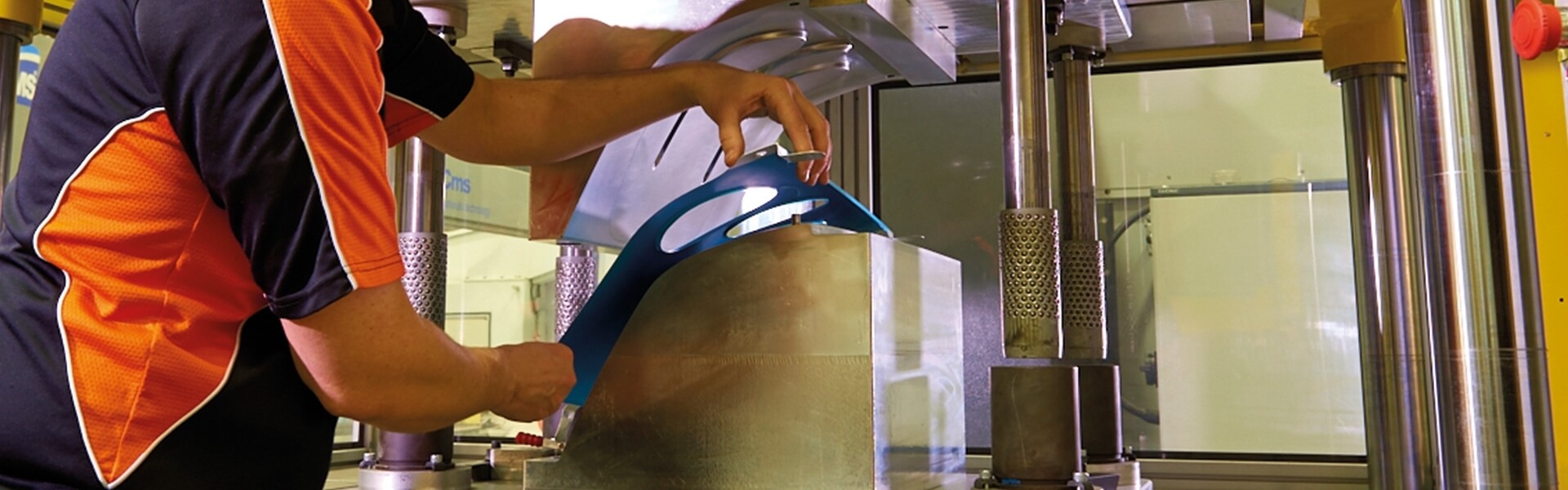

Rapid Lost Wax

WCM Produces near net cast detail with physical metal properties to production intent standards, emulating pressure die-casting. The Prototyping team utilises casting facilities in-house to build rapid printed wax models, which are then prepared on a casting tree before encapsulating them in a flask ready for burn out.

The parts are then cast under vacuum. This method is suitable for both prototyping and low volume production in any cast material, resulting in significant savings when compared to the costs of tooling.

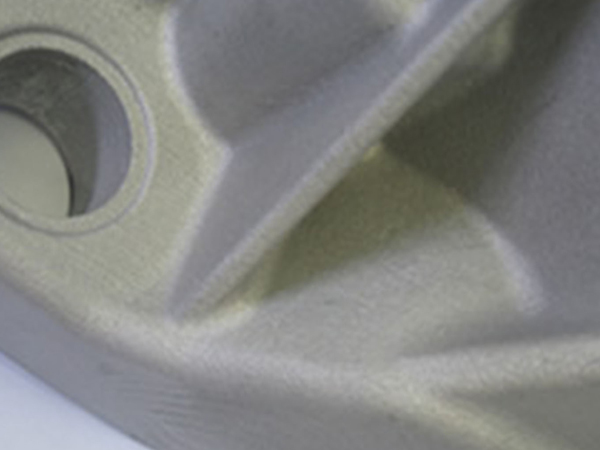

Rapid Sand Moulding

The design in this service is key as focus is placed upon designing just the mould pack for sand moulding. By utilising Sand printing machines, the mould can be made in hours in preparation for the manufacture of a metal part or a tool. At WCM, both ferrous and non-ferrous metals can be cast.

- The process accepts infinite design changes with no tooling modifications or cost implications

- Product development is radically reduced

- Hard tooling can be started much later with 100% confidence

- Can be used to support and prove FEA analysis reports

- Project cost significantly reduced

- Fault Finding by Measurement

- Reverse Engineering

- Multi-Cavity Inspection Reports

- Measurment System Analysis (MSA)

Operational Lead Times

- V6 cylinder head casting - 22 days to first off

- Powertrain bracket typically 5 days, machined - 7 days

- Manifold inlet / exhaust - 5-10 days

- Auto transmission valve body castings - 7 days

- Transmission cases, various - 15-22 days

- Concept wheels - 14 days

Experts in Casting processes and techniques support customers through the selection process, making sure your parts are made using the appropriate process and materials