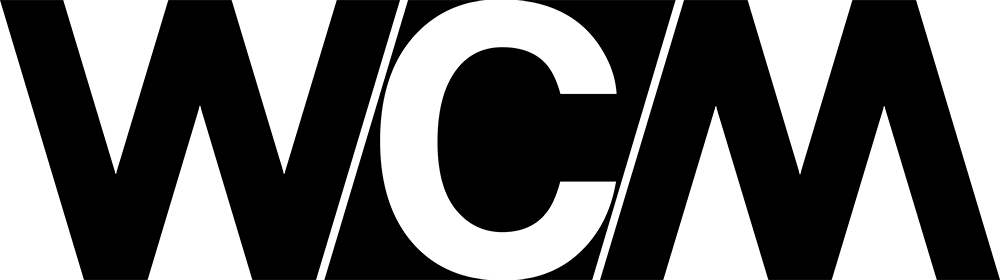

metal pressing

WCM take pride in being able to form any metal into any shape required. Dependant upon volume requirements, tooling can be provided to suit the nature of the request, from simple brackets to body panels.

For quick one-off parts WCM manufacture hammer form tooling and for higher quantities, tools vary to suit requirements. These tools can be blanking, forming or piercing tools. Multi stage tooling is also manufactured and designed in line with your production needs.

WCM work with the latest materials ranging from Deep-Drawing Steels through to High-Strength Low-Alloy Steels such as S460 to High-Grade Domex, Docol, CPW800 and Dual-Phase Steels. Many components are made in Stainless Steel, Aluminium, Titanium and Inconel

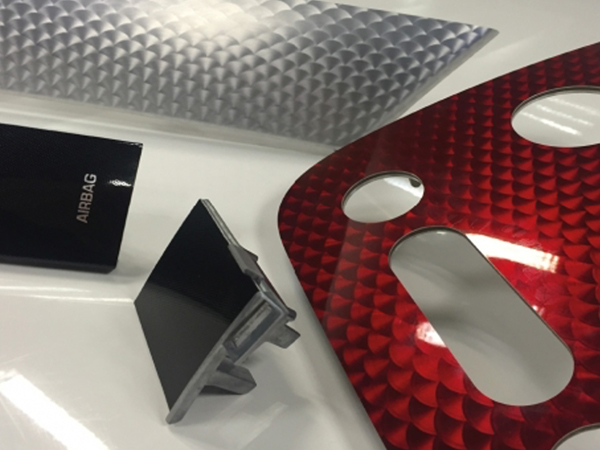

Metal Press Examples

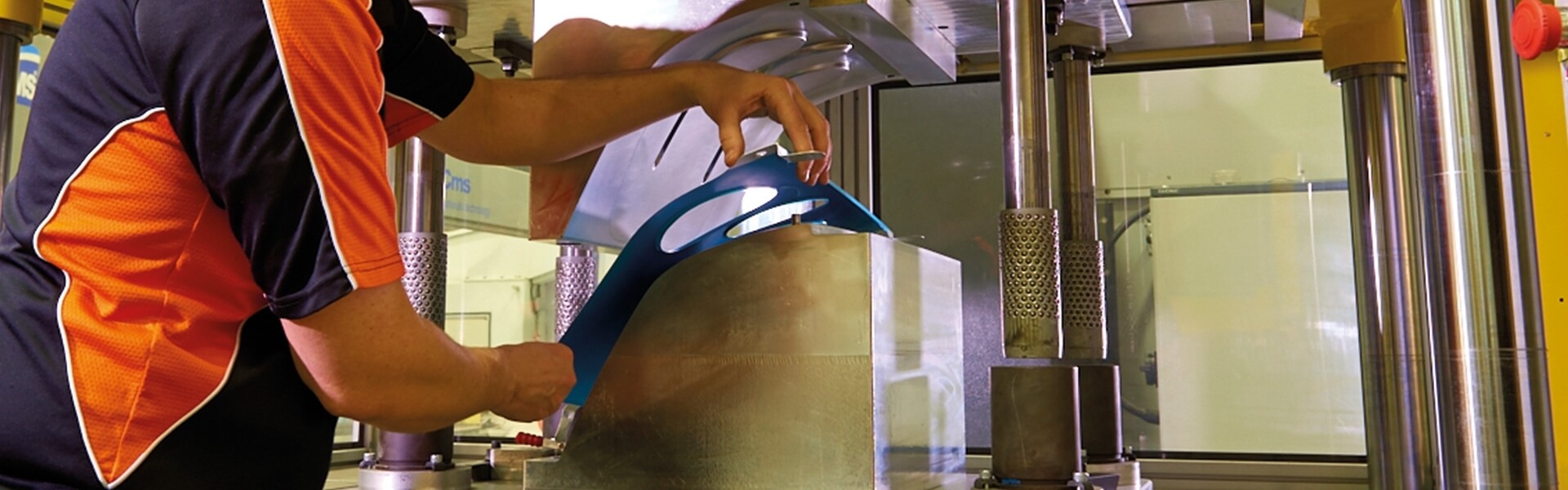

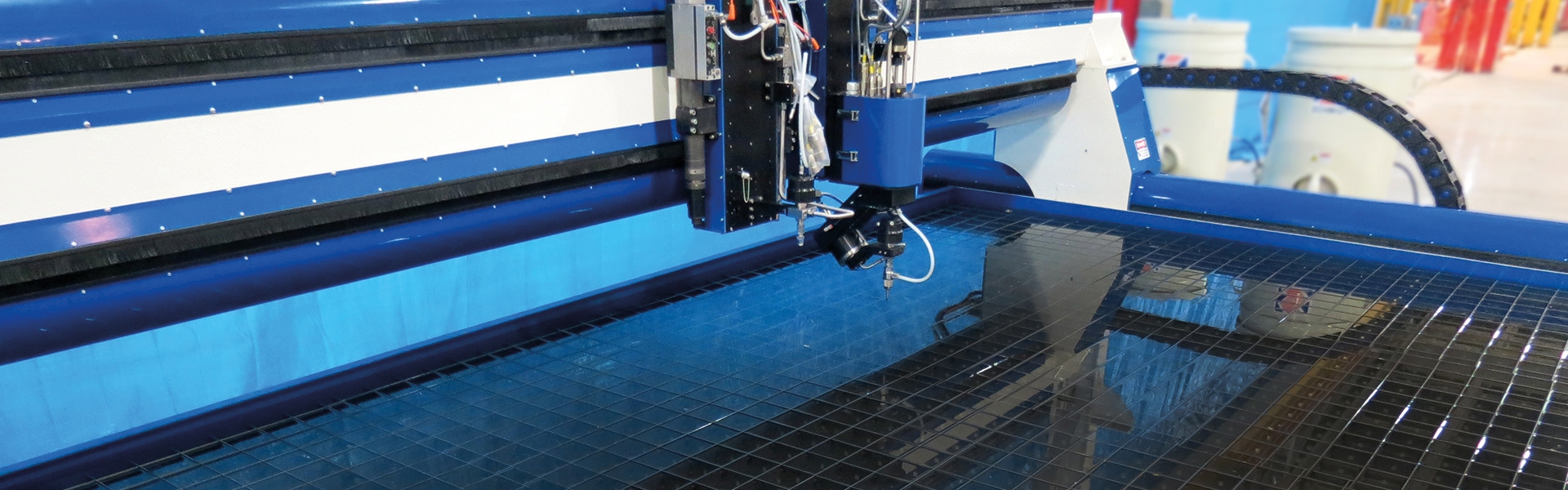

The presses at WCM range from 50 tonnes up to 800 tonnes, with a bed size of 2500 x 1250 x 970mm stroke. Using computer-controlled accumulators allows the WCM team to simulate mechanical pressing speeds and trial your production process. With the ability to fold up to 3m long, laser or cropped blanks can be CNC formed within fine limits on our brake press facility.

- Range of Metal Presses to suit part requirements

- Bonded with metal, wood and plastic substrates to make quality foiled parts

- Press Processes used for Prototype, Series and Production Volumes

Welding Services

The modern, flexible robot welding area at WCM provides higher speeds and therefore lower costs, with consistently high quality weld assemblies compared to manual processes. Once the cells are programmed, the WCM team can run any size batch, from prototypes and low volumes up to production runs.

WCM is an accomplished supplier to Automotive OEMs of Pressed Metal Parts with bonded metal,plastic and wooden substrates